Axial compressor rotor¶

NOTE: Before running this case, please read the instructions in NACA0012 airfoil incompressible to get an overall idea of the DAFoam optimization setup.

This is an aerostructural optimization case for an axial compressor rotor (Rotor 67) at subsonic conditions. The summary of the case is as follows:

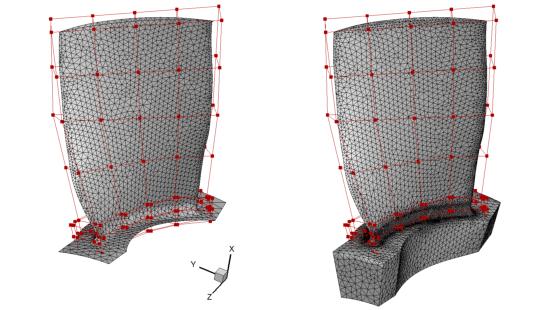

Case: Rotor67 Aerostructural optimizationGeometry: Rotor 67: an axial compressor rotorObjective function: TorqueDesign variables: 40 FFD points moving in the x, y, and z directions (120 design variables in total)Constraints: Constant mass flow rate and total pressure ratio, von Misese stress constraintRotation speed: -840 rad/s (50% design speed)Inlet absolute Mach number: 0.29Reynolds number: 0.85 millionMesh cells: 61K for fluid and 94K for solidAdjoint solver: rhoSimpleDAFoam and solidDisplacementDAFoam

The configuration files are available at Github. To run this case, first source the DAFoam environment (see Tutorials). Then you can go into the runFluid folder and run:

./Allrun.sh 4

The optimization progress will then be written in the log.opt file. The flow simulation results are stored in optOutputFluid and the solid simulation results are stored in optOutputSolid.

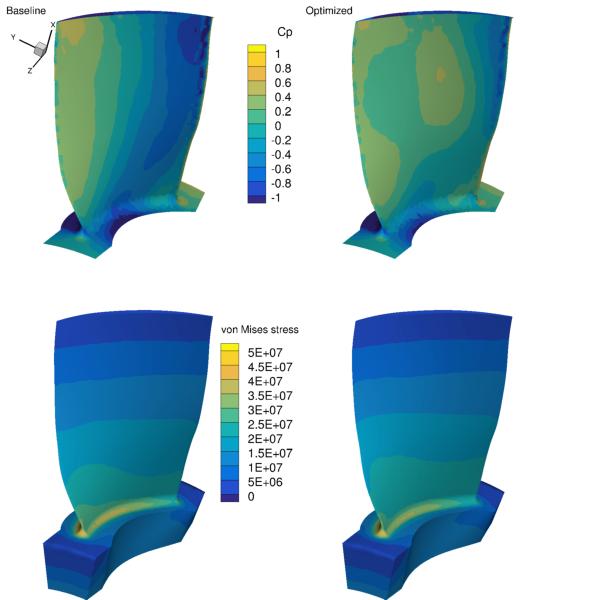

For this case, the optimization converges in 8 steps, see the following figure. The baseline design has C_M=0.01862, m=1.003 m^3/s, p1/p0=1.112, sigma=4.828e7 Pa, and the optimized design has C_M=0.01822, m=1.003 m^3/s, p1/p0=1.112, sigma=4.828e7 Pa.

The mesh and FFD points are as follows. We use ICEM to generate the triangular meshes and FFD points.

In this case, we couple two solvers: rhoSimpleDAFoam (flow simulation) and solidDisplacementDAFoam (structural analysis).

Again, they interact through file IO, so the foamRun.sh script is a bit different from that used in NACA0012 airfoil incompressible.

We also define new functions: evalConFuncs, aeroFuncs, and aeroFuncsSens in the runScript.py