Axial compressor rotor¶

NOTE: Before running this case, please read the instructions in NACA0012 airfoil incompressible to get an overall idea of the DAFoam optimization setup.

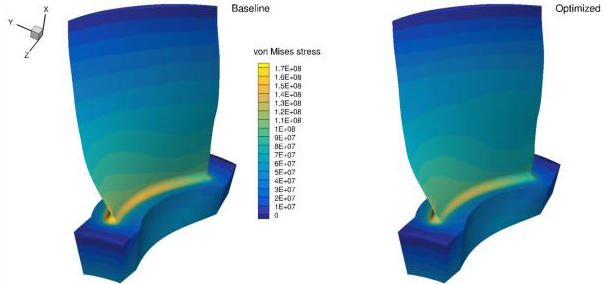

This is a structural optimization case for a axial compressor rotor (Rotor 67). The summary of the case is as follows:

Case: Structural optimization for the engine fanGeometry: Rotor 67Objective function: Maximal von Mises stressDesign variables: 120 FFD points moving in the x, y, and z directionsConstraints: NoneMesh cells: 94KAdjoint solver: solidDisplacementDAFoam

The configuration files are available at Github. To run this case, first source the DAFoam environment (see Tutorials). Then you can go into the run folder and run:

./Allrun.sh 1

The optimization progress will then be written in the log.opt file.

For this case, the optimization converges in 4 steps, see the following figure. The baseline design has sigma=1.828e8 Pa and the optimized design has sigma=1.507e8 Pa.

We use solidDisplacementDAFoam. The mesh and FFD setup are same as Axial compressor rotor. The rotor runs at 1860 rad/s.